Inqubo ye-crystallization eqhubekayo ye-Aginomoto

Uhlolojikelele

Ihlinzeka ngemishini kanye nendlela yokwenza ungqimba lwe-crystalline semiconductor ku-substrate.

Isendlalelo se-semiconductor sakhiwe ngokufakwa komhwamuko. Izinqubo zokuncibilika kwe-laser pulsed / recrystallization kuya kusendlalelo se-semiconductor ibe izendlalelo zekristalu. I-laser noma enye i-pulsed electromagnetic radiation iyaqhuma futhi yakheke njengokusatshalaliswa ngokulinganayo endaweni yokwelashwa, futhi ihlale ivezwe endaweni yokucubungula eseduze nokuqhuma okushiwo, kuya ezintweni ezifakwe kancane kancane ziguqulelwa ku-crystalline material.Ukudla okuqhubekayo nokukhipha, kanye ukugxila, izinga lokushisa, ukuminyana kwe-crystal slurry kanye nokusatshalaliswa kobukhulu bekristalu bazo zonke uketshezi kuhlala kungashintshile phakathi nenqubo ye-crystallization.

1. Ukuzivumelanisa nezindinganiso eziqhubekayo zokukhiqiza, ukunemba kokulawula inqubo yokukhiqiza okuqhubekayo kuphakeme, okukhiphayo kukhulu, ukukhiqizwa kuzinzile, futhi kulula ukuxhuma nezinye izinyathelo zenqubo, okungenye yezindlela zokuthuthuka kobuchwepheshe bemboni esikhathini esizayo.

2. Isivuno se-crystallization singathuthukiswa kakhulu, futhi imikhiqizo elahlekile etshwaleni kamama ingatholwa ngokusebenzisa indlela ye-multi-stage countercurrent, ngenkathi ihlangabezana nezidingo zomthetho, futhi kunciphisa kakhulu ukukhiqizwa kwezinto eziyingozi eziqinile.

3. Ukuhlanzeka komkhiqizo kungathuthukiswa ngempumelelo, futhi izinga lokuhlukaniswa lomkhiqizo oyinhloko kanye nokungcola kungandiswa ngokusebenzisa indlela ye-multi-stage countercurrent, ngakho okuqukethwe komkhiqizo oyinhloko kungandiswa futhi, kanye nekhwalithi yomkhiqizo. umkhiqizo wokugcina ungathuthukiswa.

4.Nciphisa ukuchezuka phakathi kwamaqoqo. Ukulawula okuzenzakalelayo ngokugcwele nokuqapha ku-inthanethi kungasetshenziswa ukunciphisa ukuchezuka okubangelwa ukusebenza okwenziwa ngesandla kanye nokungazinzi okubangelwa isinyathelo sangaphambili.

Esitezi esingaphansi sebhodwe lecrystallization ye-MSG, idivayisi ithatha inqubo yokwenza umphumela ophindwe kabili, ifilimu ekhuphukayo, ukuhwamuka kwe-decompression, isitimu esisha sinikeza ukushisa kokuqala, uma kuqhathaniswa nenqubo yasekuqaleni, le divayisi inciphisa ukusetshenziswa kwesitimu ngamaphesenti angu-50. I-Crystallization i-Self-developed Oslo elutriation crystallizer ngaphandle kokunyakaziswa

Idivayisi isebenzisa uhlelo oluzenzakalelayo lokulawula.

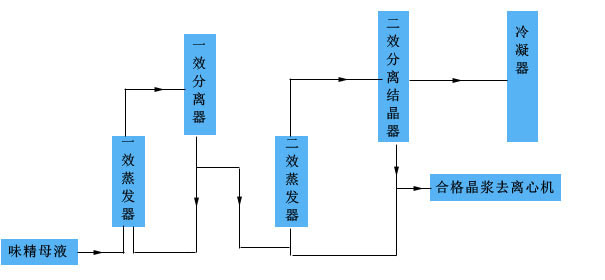

Okwesithathu, ishadi lokugeleza kwenqubo